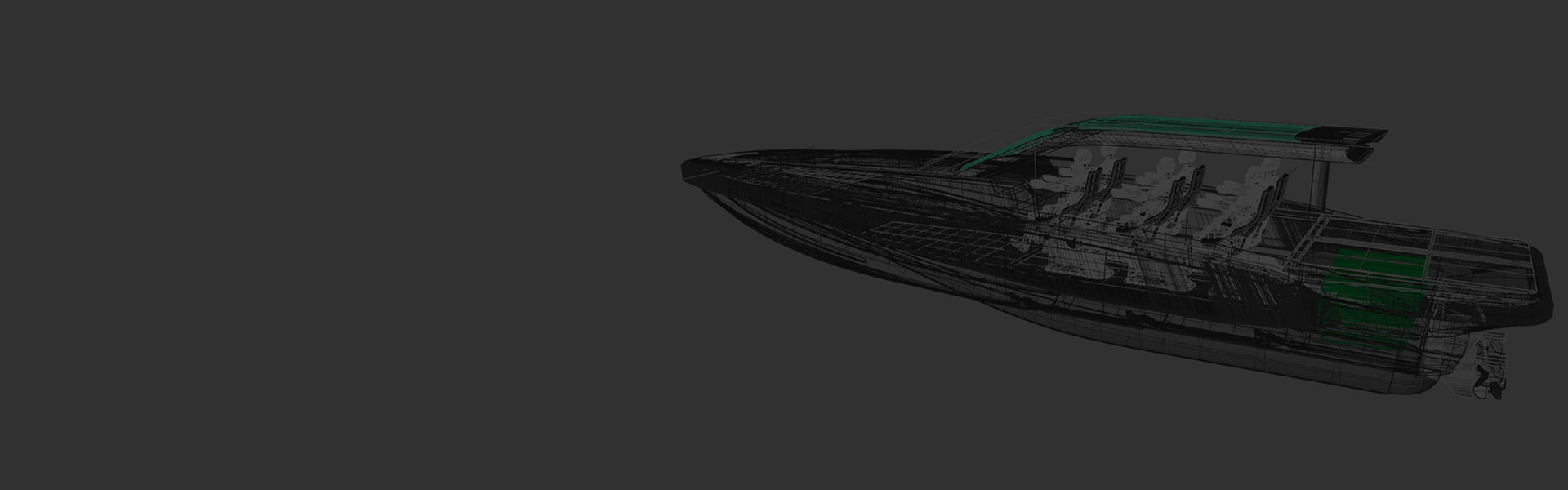

Concept Design &

Naval Architecture

3D Modelling

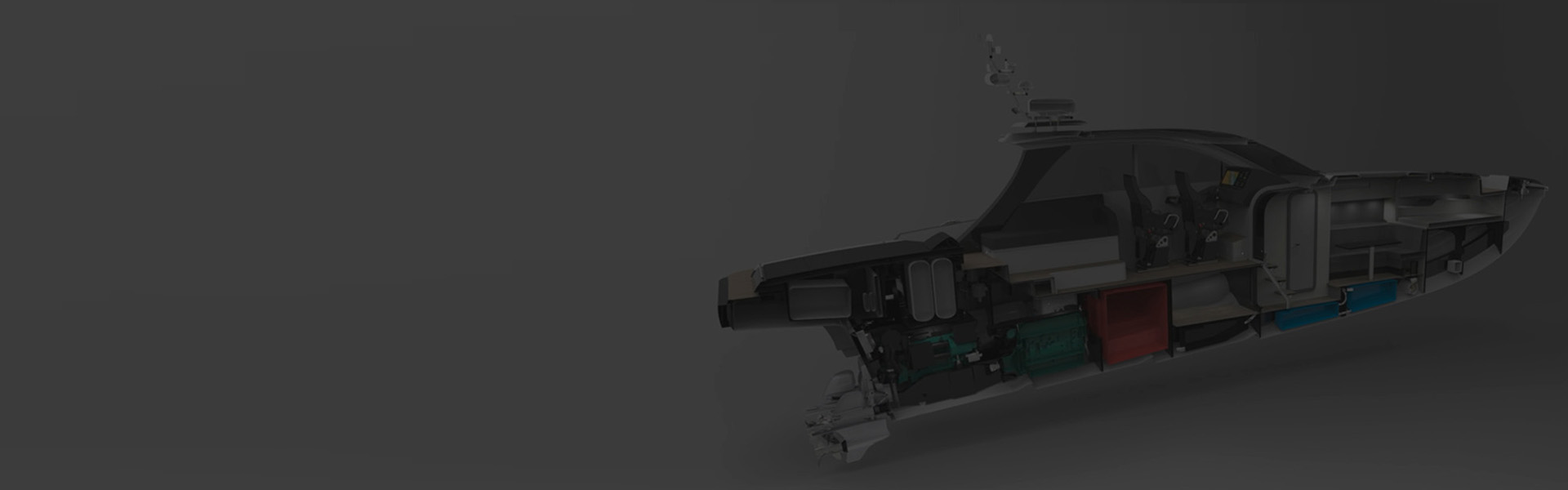

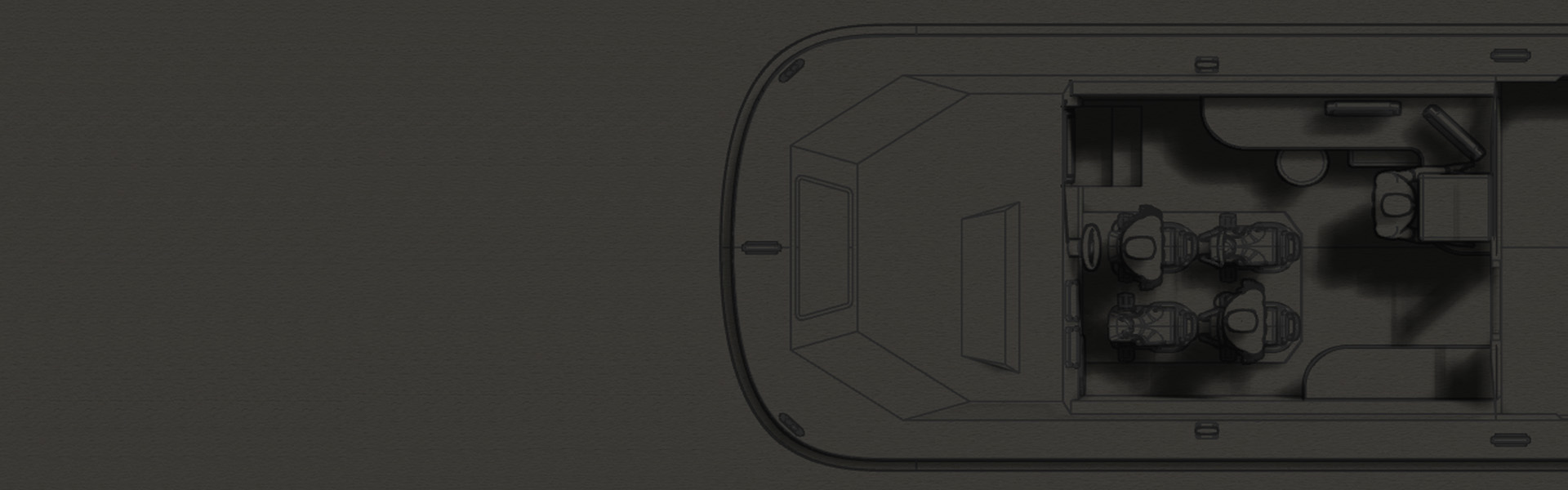

General Arrangements

& Systems Layout

Composite Structural

Engineering

Detailed Weight Sheets

& C of G Calculations

Speed, Power &

Endurance Calculations

Electrical Systems Design

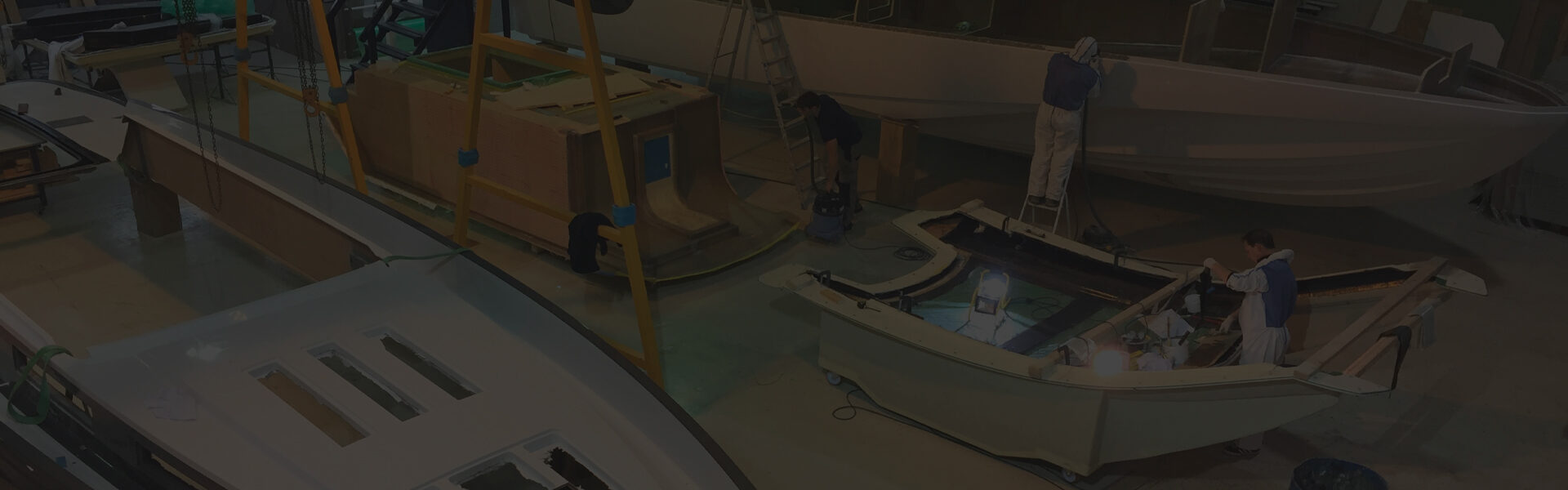

Construction

Drawings

Photo-realistic Rendering

& Animation

Tooling

Prototyping &

Sea Trials

Manufacture &

Production